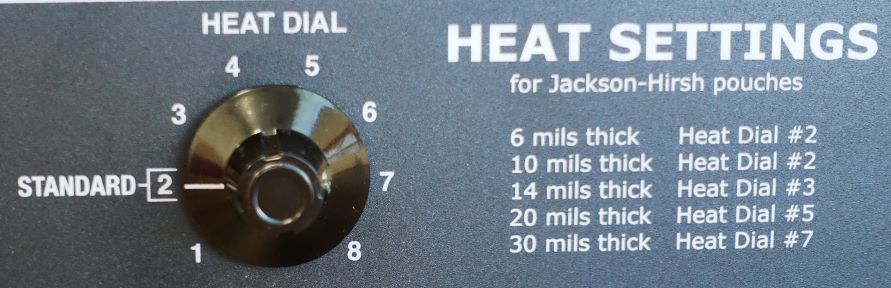

The Heat Dial on the front of the laminating machine offers 8 different heat settings, suitable for laminating plastics from thin to thick to extra-thick. We recommend setting #2 for thin 6-mil plastic (3 mils on each side). We recommend setting #7 for 30-mil plastic (15 mils each side). One mil = 1/1,000 inch.

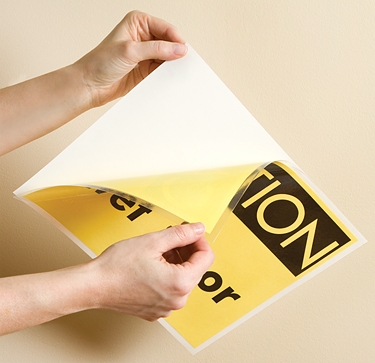

We want you to try our adhesive-back laminating pouches, which we offer in many sizes, and which can be used to laminate sticky-back safety and hazard signs and labels. Print your paper sign, laminate in one of these pouches, peel off the protective backing, and stick the sign on any flat, dry surface. Your Adhesive-Back Laminating Kit will include pouches with a permanent adhesive, plus pouches with a removable adhesive. And you can compare adhesive-backed pouches with a 3-mil front, 5-mil front or 10-mil front.

You can stick your adhesive-back safety signs to any flat, dry surface, but you may want to try mounting on one of our sign boards. Your laminator will come with a Sign Board Comparison Kit, which includes one of our aluminum sign boards, plus one of our PVC sign boards. Try them both!

Jackson-Hirsh offers a wide range of plastic laminating pouches, from 6 mils thick (3 mils each side) up to 30 mils (15 mils each side). Your laminator will come with a Thick/Thin Lamination Sample Kit, which allows you to experiment with pouches that are 6 mils thick, 10 mils, 14 mils, 20 mils and 30 mils.

Jackson-Hirsh offers 27 different products for making laminated plastic tags, from tiny 1-inch tags all the way up to jumbo tags that will hold a letter-size piece of paper. Some of the tag pouches include a special write-on surface. Your Tag Lamination Kit will include tag pouches in different sizes, different thicknesses, and with the write-on surface.

You don’t want your finished laminated sheet to come out with bubbles or waves in the plastic. This is usually a sign of not enough pressure, and too much heat.

Our laminator includes four silicon rollers, instead of the usual two rollers, to generate a flatter, smoother output. We’ve also added an extra spring to increase the roller tension.

Heat adjustment is also critical for avoiding bubbles and a smooth output. We make that easy with our Heat Dial and a thermometer on the side of the laminator. And our Heat Dial recommendations for different plastic thicknesses are printed right on the front of the laminating machine. You don’t need any special training to use our laminator.

We also recommend the use of our premium silicone-coated cardboard carriers during lamination, which protects the laminated piece and also prevents plastic goop from accumulating over time on your laminating machine rollers. We include our carriers free with each box of laminating pouches.

Our 14 rpm motor is faster than most laminators, so you can get your job done quickly. The 12.5” throat enables you to laminate papers as large as 11 x 17”. Or you could laminate several small tags or cards at once, saving time.

Our laminator is made in the U.S., features a tough steel case, solid-state heat control, permanently lubricated bearings, and forced-air cooling. It is UL listed, and carries a 5-year warranty. We offer a 30-day return privilege. We’ve been selling laminators since 1970, and many customers have used their laminating machine for 20 years or more.

Copyright 2025, Jackson Hirsh, All Rights Reserved

Website Created by Digital Design Solutions and ARENDS